Introducing the 10.1inch High-Brightness Industrial Display Module from CDS

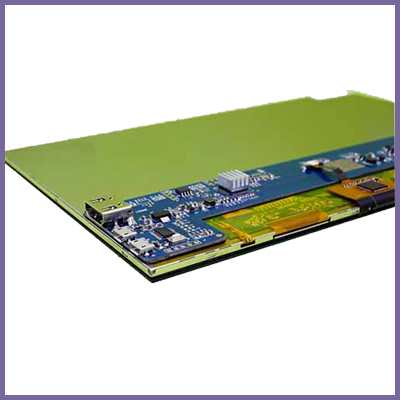

Introducing the 10.1-inch High-Brightness Industrial Display Built for Tough Environments and Crystal-Clear Visibility If you’re looking for a display that can handle demanding industrial environments and deliver outstanding visual quality, the new 10.1-inch High-Brightness Industrial Display is an exceptional choice. Designed for OEM manufacturers who need reliability, clarity, and effortless integration, this module brings together rugged engineering and premium performance for both indoor and outdoor applications. With its high brightness, wide operating temperature, robust touch interface, and flexible connectivity, this display is purpose-built for everything from industrial kiosks to outdoor digital signage. Exceptional Visual Clarity in Any Environment At the heart of this 10.1-inch display is a 1280×800 IPS TFT panel, delivering crisp, vibrant images with excellent colour accuracy.The wide 85°/85°/85°/85° viewing angles ensure consistent visibility from all directions — a must for public-facing industrial systems. The standout feature?A 900-nit high-brightness screen that cuts through harsh ambient light, ensuring perfect readability even in direct sunlight. Combined with anti-UV and anti-glare coatings, it performs brilliantly in outdoor installations. Click here for our case studies page Click here for our case studies page Rugged Touchscreen Built for Heavy Use Industrial environments demand durability, and this module is engineered to withstand it.The display features: OCA-bonded PCAP touch technology for high precision IK08-rated tempered cover glass for impact resistance Smooth, responsive interaction, even with continuous use Surface treatments that enhance sunlight readability and provide long-term UV protection Whether installed in a self-service terminal or a busy industrial control panel, this touchscreen delivers reliable performance around the clock. Engineered for Extreme Conditions Reliability is essential for OEM and industrial deployments.This display handles extreme temperatures with ease, featuring a wide -30°C to +85°C operating range, making it suitable for both freezer environments and hot outdoor climates. It also includes high-level ESD protection (Contact: ±8KV, Air: ±15KV), ensuring stable operation in electrically noisy environments. Click here for our testimonials Effortless System Integration for OEM Projects Designed to minimise engineering time, the 10.1-inch High-Brightness Industrial Display includes: HDMI and VGA interfaces for flexible connectivity USB touch interface for easy plug-and-play setup Built-in 4Ω 2W speaker for multimedia feedback Wide 9–36V DC power input, perfect for diverse industrial power systems Simple mechanical mounting, making integration into housings and enclosures straightforward Its compact design — 256.0 × 150.5 × 25.8 mm — and clearly defined active area of 216.8 × 135.5 mm make it ideal for space-limited installations. Why OEM Manufacturers Choose This Display This display is purpose-built for industrial and commercial environments where performance and durability matter most. Key advantages include: Outstanding clarity in bright and outdoor settings Long-term reliability for 24/7 operation Robust touch technology for high-traffic systems Long product lifecycle and stable supply Simplified installation and maintenance Perfect for kiosks, industrial automation systems, digital signage, medical equipment, and countless custom OEM applications. Click here for our testimonials Click here to find out more about our team Why Choose CDS for Industrial Displays? Partnering with CDS means working with a trusted leader in industrial and commercial display solutions. Our customers benefit from: High-quality engineering and innovation Fully customizable options for bespoke OEM requirements Proven reliability across Europe and the U.S. Expert guidance from concept through integration If you’re ready to enhance your product with a rugged, high-brightness display that performs flawlessly in any environment, the 10.1-inch High-Brightness Industrial Display could be your perfect solution. Want help integrating this module into your project?Get in touch with the CDS team today — we’re here to support your next innovation. Check Out Some Of Our Displays in Action https://www.youtube.com/watch?v=BnCu07hOmH4https://www.youtube.com/watch?v=94G4yub50S8&t=20s Need More Information? CALL US +44 (0)1634 791600 CLICK TO EMAIL US!